Fogg Improves P&IDs for Customers

Aug 30, 2022Holland, MI, August 30, 2022 – Fogg Filler is continually focused on improving technology that better serves our customers and the environment. Fogg has created an access database to quickly and effectively create improved P&IDs for customers. Fogg refers to their new system of creating P&ID's as the "wave of the future” because it is beneficial for everyone internally and externally.

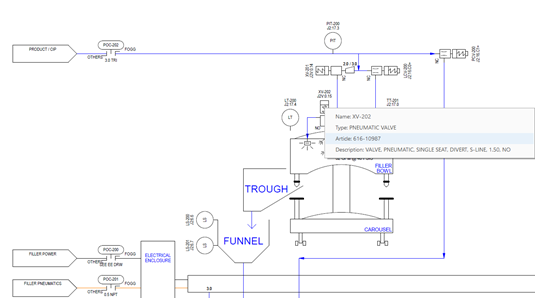

A P&ID (Process and Instrumentation Documentation) is a detailed visual diagram that displays all process components for the Fogg systems. They are engineering documents to share between the Original Equipment Manufacturer (OEM), the customer, and the integrator. This ensures they all work together, and the installation goes as smooth as possible. Previously, Fogg's P&IDs consisted of many drawings in a system called AutoCAD. The drawings were not easily readable or editable, which made installation and maintenance processes difficult.

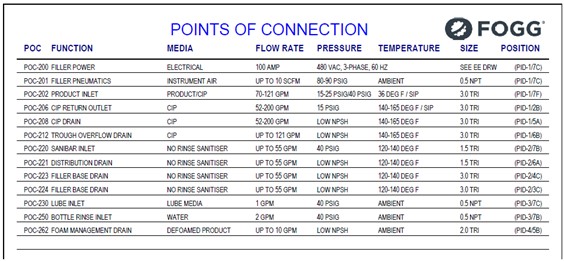

P&IDs are essential for communicating with integrators so lines can be identified and run quickly, easily, and correctly. The new P&ID system displays all this information and more in one easy-to-read document. This tool creates a point of connections list for the integrator with data on flow rate, pressure, connection size, connection type, and function. Fogg’s P&ID is an organized, interactive PDF document including a cover page, table of contents, revisions, bill of materials, and full equipment list for each individual customer. Extended Shelf Life (ESL) customers greatly benefit from P&IDs because of how complex ESL lines are. Each component and point of connection is given an identification code for easy communication. Tags are placed on the machine so the reader can follow the P&ID.

Fogg’s P&IDs are very user-friendly. Fogg has added customer-specific information such as bottle sizes, and fill rates. The P&IDs also have specifications and suggestions for lubricants for the customer’s convenience. If a customer calls in with a troubleshooting situation, Fogg can easily look up their P&ID and see exactly what the customer is referencing. Customers can click directly on graphics, and the specific part number comes up so they can easily order what they need. This ensures there are fewer errors throughout the communication process.

Fogg continues to improve technology and provide the highest level of reliability for your production lines. Please consult a Fogg sales representative to discuss your particular application or for our full line of filling and capping machines and accessories please contact our sales team at 616-786-FOGG or www.foggfiller.com

About Fogg

Fogg is a market leader in the design and manufacture of rotary liquid filling systems including rinsers, sanitizers, fillers, cappers, and cap sorters. Fogg offers tailored solutions to meet the specific needs of companies in the dairy, juice, water, spirits, pharmaceutical, chemical, and other consumer packaged goods markets. Dedicated to superior craftmanship and service worldwide, Fogg continually finds ways to enhance filling performance in all situations, including extended shelf life applications and assuring optimum production rates. Fogg is a product brand of ProMach, a global leader in packaging line solutions. As part of the ProMach Filling business line, Fogg helps our packaging customers protect their reputation and grow the trust of their consumers. ProMach is performance, and the proof is in every package. Learn more about Fogg at www.FoggFiller.com and more about ProMach at www.ProMachBuilt.com.

Media Contact

Morgan Calabrese | 1-616-786-9768← Back to Press Releases