ProMach is your partner from start to finish. Our product brands are grouped into distinct business lines that make the most sense to our customers, covering every function of the production line: Filling, Bottling & Capping, Decorative Labeling, Flexibles & Trays, Pharma, Handling & Sterilizing, Labeling & Coding, Robotics & End of Line, and Systems & Integration.

learn moreBOTTLE FILLING MACHINERY

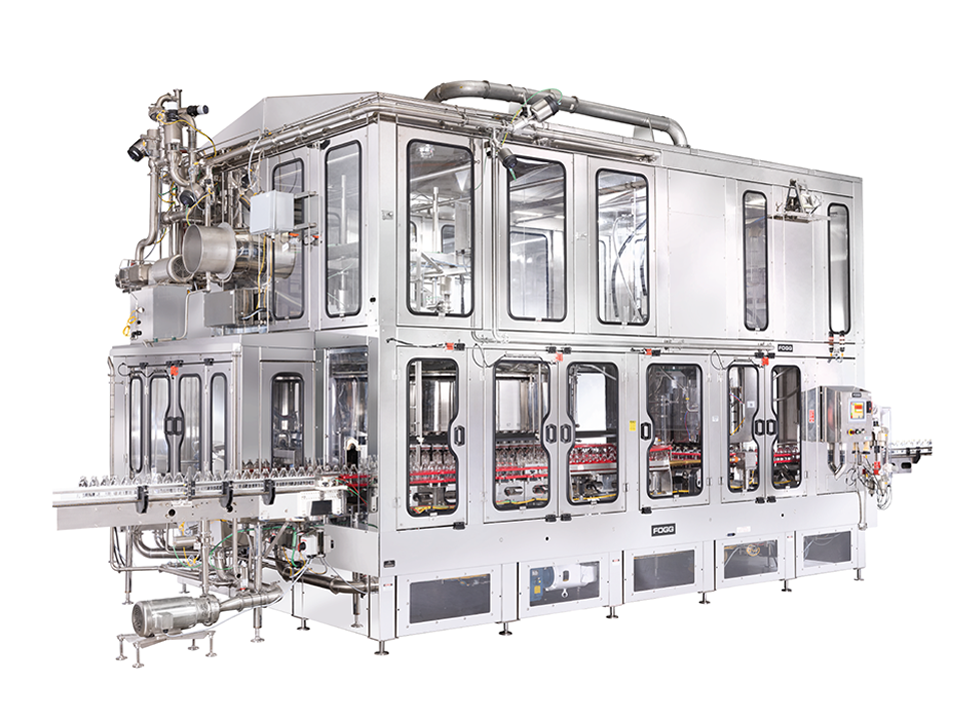

Fogg offers bottle filling equipment with speeds and neck handling technology to assure optimum production rates. From bottled water to antifreeze, juice to household products, pharmaceutical to dairy products, Fogg filling machines have proven superior in applications throughout the world.

We’ll engineer your bottling equipment to meet your specific production requirements, contoured stainless steel filler bowls up to 12 feet in diameter - up to 120 filling valves, integrated rinser and/or capping systems, and machine guarding with HEPA filtration. You can rely on Fogg’s filling machinery transfer technology for smooth container handling.

All Fogg fillers can operate as a stand-alone machine or monobloc configuration.

PMMI Technology Excellence Award Winner!